Can Seams in Your Rosin Bags Lead to Contamination?

Cannabis enthusiast and student of the art of solventless extraction

You just took a beautiful dab and now you’re sitting back to revel in the experience. The flavor hits perfectly, the melt looked gorgeous going in, and the silky smoothness of the smoke is still hanging in the air. But then you notice something. There's residue left in the bottom of your banger. Maybe it's a dark ring of carbon, a cloudy film that won't fully evaporate, or tiny streaks of discoloration that shouldn't be there.

When rosin doesn't melt completely clean, it's not just an aesthetic problem. It signals contamination, and surprisingly often, the source isn't your starting material or washing technique. It's your rosin bags, specifically the seams holding them together.

Understanding Clean Melt

Judges and connoisseurs evaluate rosin on many factors, but full melt remains the gold standard. True full melt vaporizes completely without leaving residue behind. When you heat quality rosin in clean quartz, it should disappear entirely, leaving nothing but maybe the faintest oil stain that wipes away with a cotton swab.

Leftover material tells a different story. Burnt carbon trails, cloudy residue that refuses to evaporate, discoloration in the melt pool, or visible particulates all indicate contamination entered your final product somewhere along the chain. While grow practices and washing technique certainly matter, the pressing process itself can introduce problems even when everything upstream was handled perfectly.

Identifying the Source

If your wash is clean and your drying process is dialed in, but rosin still leaves residue, it's time to examine your bags more closely. Take a pressed bag and inspect it under magnification, particularly along the seams. You'll often observe discoloration tracking along the stitching, sometimes passing from one side of the seam straight through to the other.

This pattern reveals the contamination pathway. Something traveled through the seam during pressing, bypassing the mesh filtration you carefully selected. The culprit is the stitch holes themselves, creating unintended gaps in your filtration barrier.

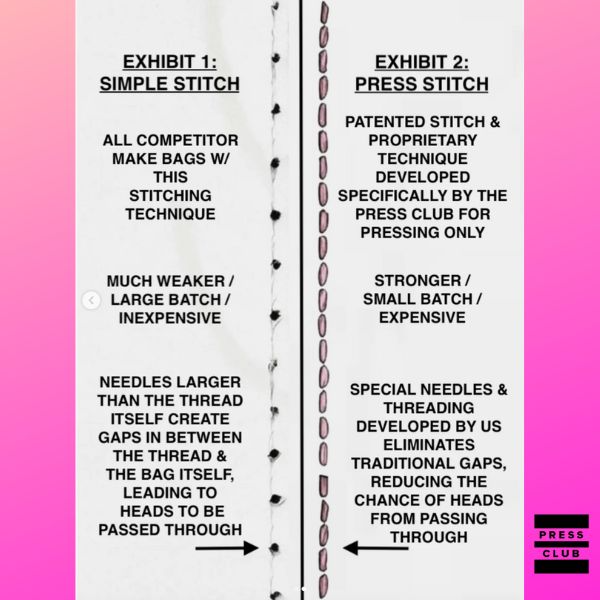

Why Stitch Holes Create Problems

Here's the issue most extractors don't realize: stitch holes in traditional rosin bags often measure larger than 25 microns. That's bigger than the mesh material you're using to filter your resin. When you select a 25 micron bag expecting that level of filtration, the seams can undermine that precision entirely.

These gaps allow plant material, lipids, and other contaminants to bypass your intended filter and contaminate otherwise clean rosin. You might be pressing beautiful hash through a 25 micron screen, but if the seams are leaking particulates through 30 or 40 micron stitch holes, your effective filtration is compromised.

The result is straightforward: reduced purity, increased residue after dabbing, and subpar melt quality that doesn't reflect the actual grade of your starting material.

Folded vs Stitched Construction

One solution eliminates seams entirely through folded mesh construction. Folded bags have no stitching, removing the contamination pathway completely. For extractors who can use them, folded bags offer genuine advantages in filtration integrity.

But folded construction isn't always practical. Certain press sizes, production scales, and form factors require stitched bags. Completely abandoning stitched construction would limit options for many professional extractors who need specific bag configurations.

The answer isn't choosing between stitched and folded. It's developing stitched construction that performs as cleanly as folded alternatives.

Pink Stitch Technology Is the Answer

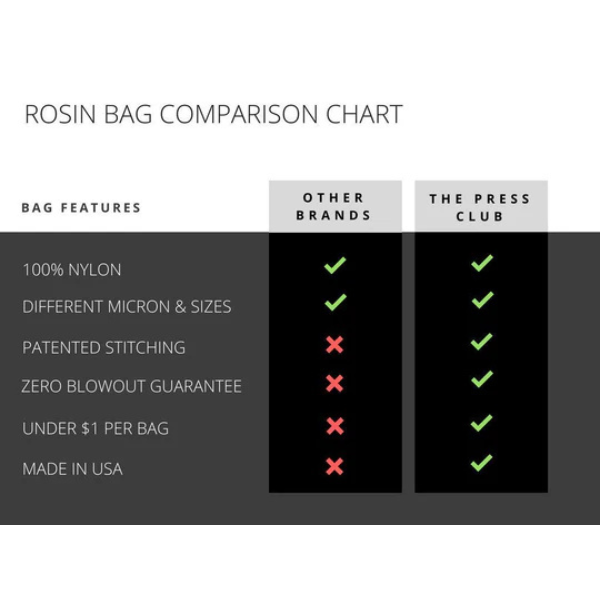

The Press Club developed our proprietary Pink Stitch specifically to solve seam contamination in stitched rosin bags. This isn't standard thread with a different color. It's custom-engineered material that creates exceptionally tight seams, drastically reducing the contamination risk that plagues conventional stitching.

Our pink thread produces stitch holes significantly smaller than traditional bag construction, bringing them in line with or below the micron rating of the mesh itself. When you press through a Pink Stitch bag, you're getting the filtration performance you selected without seam-based contamination undermining that precision.

This technology was designed specifically for solventless extractors who demand the cleanest possible press. We developed it because we saw the problem, understood the chemistry behind why it mattered, and committed to engineering a real solution rather than accepting compromised filtration as inevitable.

The Ultimate Solution: Double Bagged Bags

For extractors chasing absolute zero-compromise cleanliness, we've taken seam technology even further with our Double Bagged Bags, or DBB. This system uses an inner and outer bag configuration that completely removes seam contamination from the equation.

The DBB design ensures that even if microscopic amounts of material pass through any stitch holes, they're caught by the outer bag before reaching your collection parchment. It's redundant filtration at the seam level, perfect for high-end processors, competition entries, and anyone who refuses to accept any contamination in their final product.

This approach represents the current peak of rosin bag technology for eliminating seam-based contamination while maintaining the practical advantages of stitched construction.

Actual Performance in the Lab

Hash makers using Press Club bags consistently report cleaner melt and reduced post-dab residue. Whether you're entering competitions, serving connoisseur markets, or pressing for personal consumption, reducing contamination at every stage improves your final product's quality and the experience it delivers.

The difference becomes obvious when you compare pressed bags side by side under magnification. Standard stitching shows clear discoloration tracking along seams. Pink Stitch bags show minimal to no seam contamination. DBB configuration shows essentially zero contamination pathway through the bag structure.

These aren't theoretical improvements. They're observable differences that translate directly to what's left in your banger after a dab.

Don't Let Your Bags Compromise Your Work

Clean melt reflects the entire chain of decisions and techniques from cultivation through consumption. Your starting material matters. Your washing technique matters. Your drying process matters. And critically, the filter between your hash and the heat matters just as much as any other stage.

If you're serious about solventless extraction, you need to be equally serious about every component in your process. Rosin bags might seem like a simple commodity item, but the engineering behind their construction directly impacts your final product's purity.

With Pink Stitch technology and Double Bagged Bag options, The Press Club ensures your seams stay sealed and your rosin stays pure. Because you've invested too much time, skill, and care into growing and processing premium material to let inadequate bags compromise it at the final stage.

Thoughts? Let us know by joining our secret Facebook group. Hang out with a community of like-minded solventless heads like yourself. Ask our head extractor questions, share your latest press and learn from hobbyists and experts in the industry.

Leave a comment

Please note, comments must be approved before they are published