How To Double Bag Your Rosin Bags

Todde Philips

🇺🇸 Retired veteran, father, rock-climbing expert & rosin connoisseur

Rosin bag blowouts are one of the most frustrating and costly occurrences for rosin extractors, so a lot of time and energy goes into preventing these gut-wrenching disappointments at the press. Using high quality rosin bags is a great start to preventing blowouts. Other techniques, such as double bagging, help your rosin bags perform at their highest level while subject to heat and pressure during extraction.

So why should you consider double bagging your rosin bags?

If you're already following best practices like choosing the right micron size, pre-pressing, and preheating your starting material, double bagging your rosin bags can give you that extra edge to reduce the likelihood of blowouts. Given that all other variables are correctly dialed-in, most blowouts occur when extracting hash rosin due to the heavy flow of rosin out of the bag.

While blowouts can occur with any starting material due to user error (e.g. overfilling bag and using excessive pressure), blowouts when extracting rosin from bubble hash become more likely as massive amounts of oil flow creates excessive pressure within the rosin bag.

The volume of rosin produced through squishing flowers is generally less than what's produced from the same amount of hash, so an excessive flow of rosin overwhelming the rosin bags is less likely to occur with flower.

When pressing bubble hash, blowouts tend to happen when rosin is being produced faster than it can effectively pass through the filter and escape the bag. The pressure from the flow of rosin being created inside of the bag overwhelms the filter's ability to function, causing the rosin to escape through other means, namely breaking the seams of the bag and forcing its way out.

In addition to double bagging your rosin bags, properly controlling the speed at which rosin is extracted, as well as its flow through the filter bag and away from the plates, are key to reducing blowouts. Remember to preheat your starting material and increase pressure slowly throughout the press, which helps maintain a slow and consistent flow of rosin through your filter bags. Use the directional flow method of folding parchment paper to route your rosin quickly and efficiently away from the plates so a steady and unobstructed rosin flow is possible.

Ensure that you're filling the bags evenly and only up to a quarter inch thickness. You don't want thick, over packed bags as this will increase the chances of a blowout. Properly closing off rosin bags with a quarter inch fold of excess material at the opening of the bag and pre-pressing your material are other techniques that help prevent blowouts. Use a pre-press mold designed for rosin extraction like these from The Press Club.

Double bagging your rosin bags is the final step that can help save you from wasted cannabis material, lost time, and needless tears. The benefits of double bagging are both preventative and corrective. Double bagging is preventative in that it adds to the rigidity and structure of the rosin bags, strengthening the integrity of the filters and decreasing the likelihood that either seam will burst under high volumes of rosin production. Double bagging is corrective in the case that the inner bag blows, then the outer bag will help contain the starting material and reduce contamination in the final product.

How To Double Bag

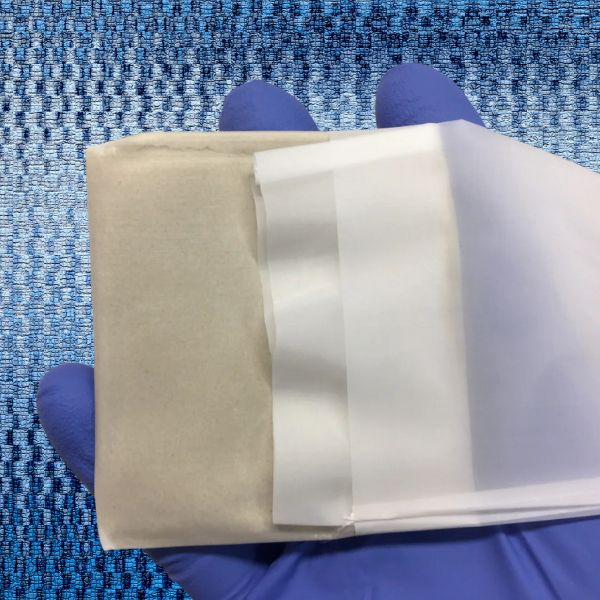

To properly double bag your rosin bags, use a larger micron bag on the outside with your target micron on the inside. For example, if you're pressing for a 37 micron rosin extraction, you'll put your starting material into a 37 micron bag and then that bag inside a 220 or 160 micron bag of the same dimensions.

After the 37 micron is packed properly (no more than a quarter inch thickness) fold over the top quarter to half inch of material at the opening of the bag and place it into a pre-press mold. Pre-press the material to ensure there are no gaps or inconsistencies in the material. After the pre-press, the material should feel solid and firm between your fingers.

Next, take the filled rosin bag and place it inside a 220 micron bag of the same dimensions, with the folded end of the first bag going into the bottom of the larger bag. Also make sure that the seams along the sides of both bags line up with each other. Ensure that the folded tops of the rosin bags are facing opposite directions, as opposed to the folded tops being on the same end. This keeps the inner bag sealed inside of the outer bag.

Once the smaller micron bag is inside the second bag, cut off any excess material at the top of the outer bag to allow a quarter to half inch fold. Fold the material over to seal the bag and then check with your fingers to make sure the material is still spread evenly within the bags. One last run in the pre-press mold and your double bagged setup is ready to go!

Conclusion:

Blowouts are more often than not the result of user error. However, when you're pressing rosin from high quality bubble hash, a second bag helps to ensure that the heavy flow of rosin through the filter bags won't overpower the seams. We've found that a 220 micron bag on the outside performs better than some of the other smaller micron sizes. We recommend double bagging with a 160 or 220 micron bag for that added reinforcement and pressure control.

FREQUENTLY ASKED QUESTIONS

Why do you double bag rosin bags?

Double bagging rosin bags means placing one rosin bag inside another for rosin extraction, so the cannabis material is contained within two layers of filter bags. This provides better structural support for the source material and reduces likelihood of blowout when pressing bubble hash.

How do you double bag rosin bags?

Place a filled rosin bag inside an empty rosin bag, so the cannabis material is now wrapped within two layers of filter bags. Ensure the seams of the bags are running parallel to each other, and that the openings of the bags are facing opposite directions. 160 micron bags are often used as the outer bag.

What is the best brand for rosin filter bags?

The Press Club makes premium rosin filter bags constructed with food grade nylon and held together with a proprietary stitching, and backed by a Zero Blowout Guarantee.

Which way do the seams go when you double bag?

The seams along the side of both bags should line up together, one over the other. It's best to avoid alternating the placement of the seams.

Do you need to use the same micron size bag to double bag?

You can use the same micron size, or different sizes. If using different sizes, place the larger size (160 or 220 micron is good) on the outside. If you use the same size micron bag, you'll get more filtration and potentially less lipids and other contaminants in your rosin. Larger bags on the outside are not as effective for additional filtration but act as support and blowout protection.

Leave a comment

Please note, comments must be approved before they are published